LUBRICITY ADDITIVE IFO LUBRICOR

Standard lubricating additives are composition of tall oil fatty acids (TOFA), but every year the demand of biodiesel productions for tall oils, which are raw materials for the production of TOFA, increases. Building of new bioprocessing plants and raising consumption of forest chemicals as raw materials for biodiesel production may lead to price boost or reduced availability of TOFA in the future.

According to the “European Union: Biofuels Annual, June 29, 2020, Attaché Report (GAIN)” report, the consumption of tall oils and fatty acids has increased byabout 50% over the past 5 years.

FEEDSTOCK USE FOR BIODIESEL + RENEWABLE DIESEL (HVO) (1,000 MT)

Calendar year | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | 2020 |

Resin industry (tall oil, fatty acids) | 60 | 220 | 335 | 370 | 559 | 444 | 604 | 667 | 738 | 765 |

Also one of the famous European bioprocessing plants UPM Lappeenranta Biorefinery UPM Lappeenranta Biorefinery | UPM Biofuels notes that “global biofuel consumption will continue to grow steadily until 2030”.

In this regard, IFOTOP company, identifing problems before they arise, has developed a based on own production innovative lubricating additive IFO-LUBRICOR.

Comparative table of the IFO LUBRICOR lubricant additive and standard 100% TOFA

| Acid index, mg KOH/g | Less than 50, there is no negative effect on the diesel fuel acidity (the norm is not more than 5 mg KOH per 100 cc of fuel) | More than 140-190, a negative effect on the diesel fuel acidity (it is necessary to monitor compliance with the norm of not more than 5 mg KOH per 100 cc of fuel) |

| Precipitation amounts in Diesel Oxidation Stability Test | No negative influence (norm not more than 25 g/m3) | Double bonds in TOFA can oxidize and negatively affect the diesel fuel oxidative stability (it is necessary to monitor compliance with the norm no more than 25 g/m3) |

| Diesel additive compatibility | No negative impact on the depressants effectiveness | May reduce the depressants effectiveness and adversely affect the Cold Filtering Plugging Point (CFPP) of fuel |

| Corrosion protection | Inhibits corrosion | No anti-corrosive properties |

| Low temperature properties | The flowing point is not higher than -10°C, the viscosity ratio at +20°C is not higher than 35 mm2/s |

|

| Wear patch according to the HFRR method at a dosage of 25-250 ppm (depending on the original fuel properties) | Less than 400 mcM (the norm is less than 460 mcM and a quality margin is required corresponding to the method error of 60 mcM |

|

| The cost | IFO LUBRICOR is equivalent to the cost of the currently used 100% TOFA | |

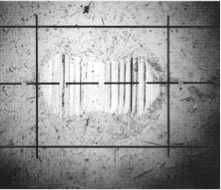

Lubricity tests were performed

using the HFRR method

on the PCS Instrumnet

The wear scar is determined by the HFRR method according to the principle of metallic wear during high-frequency reciprocating movements of the ball in contact with the plate.

As a result of the experiment, wear scar, friction coefficient and film thickness at the point of contact with the ball are observed. The diesel fuel specification norm for the wear scar should not exceed 460 microns. To avoid fuel rejection, it is recommended to provide a wear spot with a margin of not more than 400 microns, since this method has an error of 60 microns.

The IFO product portfolio for fuels includes IFO Antigel for diesel fuel and IFO Gasoline modifier.